Electric Tuggers Provide Versatile, Ergonomic Material Transfer

Utilized in manufacturing, assembly, warehousing, and distribution, electric tuggers help workers move heavy loads in multiple industries and applications. These compact, motorized units typically incorporate two large fixed wheels and two spinning casters. A single handlebar control allows an operator to direct the tugger’s travel and speed. This construction enables electric tuggers to provide versatile, ergonomic material transfer.

Powered by rechargeable batteries, electric tuggers are highly customizable. They can incorporate a broad range of hitch styles and connection options. This permits them to attach to different cart styles. Depending on their design, electric tuggers can tow loads up to 100,000 pounds.

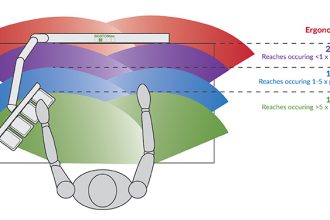

Electric Tuggers Improve Worker Ergonomics

Often deployed to eliminate the ergonomic strain associates experience when pushing carts, electric tuggers can pull multiple wheeled carts simultaneously in a train with virtually no manual effort. This significantly reduces the risk of back or shoulder injuries that result from the pushing and pulling forces associated with stopping and starting manual cart movement.

“Whether they are moving heavy machinery, pallets, or carts, electric tuggers improve productivity, reduce labor costs, and increase safety,” noted Ray Erbe, President and Chief Technical Officer at Electro Kinetic Technologies. The company is a member of the Ergonomic Assist Systems & Equipment (EASE) Council of MHI. “To ensure an electric tugger will perform as expected, however, it’s important to work with a supplier who can help specify the best configuration.”

Load Rating Capacity Critical

The load rating capacity is the most important information needed when specifying an electric tugger, said Erbe.

“Most people assume that the total weight of the cart and its payload equals the maximum rated capacity of the tugger,” he explained. “For example, if the payload and the cart weigh 5,000 pounds, then it may appear that the application needs a tugger rated for 5,000 pounds. However, that’s probably not the case.”

The reason, he continued, is drawbar force. “To get the cart moving, force has to be applied,” said Erbe. “There are two levels of drawbar force. Instantaneous duration drawbar force is a short burst—typically lasting 1 to 3 seconds—applied by the tugger to impel the cart to move. Once the cart is in motion, continuous duration drawbar force is what keeps it moving.”

Drive Wheels and Casters: Key Components of Electric Tuggers

Of the two, the instantaneous drawbar force required to move the heaviest cart and payload is the one that guides the selection of a tugger. The diameter and material selected for the drive wheels and casters also contribute significantly to the electric tugger’s load rating capacity, Erbe continued.

Of the two, the instantaneous drawbar force required to move the heaviest cart and payload is the one that guides the selection of a tugger. The diameter and material selected for the drive wheels and casters also contribute significantly to the electric tugger’s load rating capacity, Erbe continued.

“There are lots of different types of caster and wheel materials, including forged steel, polyurethane, phenolic plastic, and molded rubber. Each has different performance depending on the floor surface and the diameter of the wheel,” he said. “A knowledgeable supplier can help determine the optimal wheel characteristics to ensure the electric tugger can generate enough instantaneous drawbar force to move the carts it tows.”

Find More Ergonomic Solutions from EASE Council Members

Looking for more ergonomic material handling equipment? Check out the Ergonomic Assist Systems & Equipment (EASE) Council of MHI. The EASE Council offers a broad range of educational resources on its website. These include presentations and seminars, technical papers, checklists, and ergonomic articles. Further, its members are available to consult, answer questions, and offer advice on ergonomics best practices and safe equipment use.