Pedestrian And Traffic Barriers: Where They Should Be Used And What They Protect

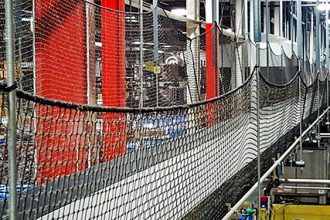

Installing pedestrian and traffic barriers within warehouses, distribution centers, factories, manufacturing facilities, and other industrial buildings protects personnel from hazards such as vehicles and other dangerous equipment. With these barriers or guardrails in place, a physical separation is created to keep employees safe. In a recent webinar presented by the members of the Protective Guarding Manufacturers Association (ProGMA), participants learned both about “The Purpose of Pedestrian and Traffic Barriers,” as well as the different types of available solutions.

The presenters noted four key reasons to utilize pedestrian and traffic barriers in facilities, all of which carry the potential for significantly higher costs than those associated with installing these guarding systems. They include:

- To reduce the risk of a forklift colliding with a person. Citing OSHA statistics, the webinar noted that approximately 35,000 forklift accidents happen annually that result in serious injuries, and 85 of those result in a fatality. Such accidents are not only tragic, but also costly in terms of downtime, rising insurance rates, increased liability, lost efficiency, and even the potential for negative publicity. By utilizing these guarding solutions, pedestrian pathways are clearly delineated to both workers on foot and those operating forklifts and other material handling vehicles. They serve to increase the visibility of safe travel paths and to reinforce separation of the two traffic patters.

- To shield inventory, structures, or equipment. These guarding solutions can be installed to protect expensive assets against potential impacts from forklifts and their loads. In addition to the danger associated with a collision — potentially resulting in damage to an electrical system, racking structure, machinery, or other equipment — replacing or repairing those items can be expensive. Further, the associated downtime required to do so is another costly expenditure.

- To optimize workflow by efficiently routing traffic. Barriers can be used to route and direct foot and vehicle traffic in a specific direction, increasing efficiency by shortening the distance pedestrians need to travel between processes. Additionally, with the COVID-19 pandemic, facilities are increasing using barriers to separate personnel and minimize interpersonal contact while routing them to key areas — such as washing stations or the time clock.

- To create and reinforce a culture of safety. The presence of these guarding solutions serves as a visual reminder to workers that their safety is valued by the operation. By making an effort to minimize their risk in hazardous situations with physical barriers, a company demonstrates the importance of safety to its personnel. It also reinforces employees’ shared responsibility to maintain a safe environment.

The webinar hosts also shared insights into the different types of pedestrian and traffic barriers. Key types include:

- Visual Indicators. Simply by using safety yellow paint or tape on the floor or walls alerts workers that there is a need to be more aware of potential dangers in a given area. While these approaches do not provide any physical protection, they still increase awareness and can slightly reduce risks.

- Physical Delineators. Handrails, which are a lighter form of guardrail that generally provide minimal impact protection, can be used to prevent personnel from leaving a walkway and stepping into a traffic path.

- Impact Barriers. These guardrails are designed and engineered to absorb and deflect the impact of a vehicle. In order to maintain safety, it is extremely important that the guardrail used is sufficiently strong enough to withstand the potential impact forces to which it might be subjected. That is, the design and construction of the guardrail should be suitable for the weights and speeds of the vehicles in circulation within the facility.

The webinar is available for viewing online.

Looking for more information about guardrails and protective barriers? The members of the Protective Guarding Manufacturers Association (ProGMA) are available for guidance and recommendations.