When OSHA Regulations Don’t Cover Your Specific Guarding Scenario, Refer To ANSI Standards

When considering guarding devices that protect personnel from hazards that could result in an injury, it’s important to refer to the mandates of the Occupational Safety and Health Administration (OSHA). As the top regulatory agency in the U.S., compliance with OSHA’s codes is the law. However, because OSHA’s protective regulations must cover a broad range of scenarios and situations by necessity, it can sometimes be challenging to determine the best practice for installing safety devices and equipment in a specific application.

For this reason, the American National Standards Institute (ANSI) verifies standards that are developed by end users, manufacturers, industry professionals, consultants, and industry associations, such as the Protective Guarding Manufacturers Association (ProGMA). While use of the best practice recommendations in ANSI standards is voluntary, their contents typically address specific situations that OSHA does not. Additionally, the contents of all ANSI standards cannot violate any OSHA code; therefore, by following an ANSI standard, OSHA requirements are also being met.

ProGMA has developed and published two ANSI standards — available for purchase — to address the design, construction, and testing of two types of protective guarding. These are safety and injury prevention applications and methods about which OSHA does not provide specific regulations. They include:

- ANSI MH31.1 Steel Mesh Containment Panels Used in Pallet Rack and Vertical Storage System Applications: Performance and Testing Requirements. It provides both guidance and information about design, operating, and testing practices to assess the amount of deflection a specific steel wire mesh containment panel might experience under a quantifiable impact load. The standard also details performance criteria and operational requirements to help interested parties as they are determining the optimal way to use these panels in their operations.

- ANSI MH31.2 Test Method for Crash Testing Industrial Guardrail Barriers and Barrier Posts. It was developed because ProGMA recognized a need to standardize performance and design criteria for the proper utilization of industrial guardrail and post systems. Prior to its publication, no standardized test method had been established to assess the crash performance of these protective devices. That made it difficult for potential purchasers to compare various product options.

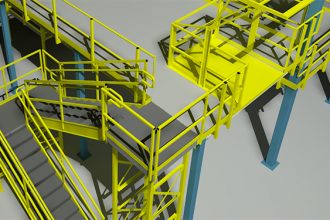

Additionally, the members of ProGMA are available to review and advise on potential guarding solutions for specific applications not addressed directly by OSHA regulations or by ANSI standards. They further offer a list of Frequently Asked Questions (FAQs), a Protective Guarding Search Tool, and a Protective Guarding Checklist to help ensure compliance and safety throughout key facility areas, including: loading docks and outside the facility; indoors on the ground floor around machinery, aisleways, and pallet racks; and overhead around racks, conveyors, mezzanines, elevated work platforms, and pick modules. Visit ProGMA’s website for more information.