ENVIRONMENTAL CONTROLS AT THE LOADING DOCK

Environmental controls can seal the deal when designing a safe and productive facility.

For any architect looking to build out a strong industrial facility, controlling the environment at the loading dock is a critical aspect of maintaining safety, quality, and efficiency. There are various challenges that arise due to the fluctuation of temperature, pest intrusion, and weather conditions that can negatively impact daily operations. These challenges can affect energy loss, quality inspection, contamination concerns, product damage, safety hazards, and employee comfort, among other issues.

To address these challenges, regulatory standards such as Current Good Manufacturing Practice (CGMPs) have been implemented to ensure that manufacturing processes meet the basic objectives of maintaining identity, strength, quality, and purity of pharmaceutical products. These regulations are enforced by the Food and Drug Administration (FDA) to maintain quality and assure consumers of their safety.

Keep it Chill…

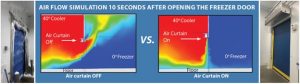

One of the most common challenges faced at the loading dock is cold storage, where temperature control is crucial. Every time the door opens, outside air and freezer air mix, leading to water, fog, and ice buildup around the doors, which can create unsafe conditions for workers and equipment passing through. With the addition of industrial air curtains, facilities can create a thermal barrier of air and prevent the mixing of outside air – eliminating these hazardous conditions.

Similarly, high-speed doors can help prevent frost and control the amount of air that comes in and out. The soft bottom edge and side guide of each freezer door curtain is designed to create a tight seal and act as an insulated curtain, while energy-efficient materials prevent energy loss and ice buildup.

Seal the Deal…

Dock levelers, seals and shelters also play a crucial role in environmental control. Vertical storing or telescoping dock levelers provide a 360° seal at the door, which helps to prevent air infiltration. Both dock seals and shelters can help maintain a consistent seal and eliminate light intrusion – with seals best serving docks with same size trucks, and shelters best serving warehouses that have trailers of different sizes coming in and out. The use of gap hooks for the side curtains and light-eliminating pleats on the head curtain can assist in FDA compliance for food and pharmaceutical industries by providing a tight, consistent seal while allowing full unobstructed access to the trailer.

Finding a reliable supplier is the first essential step in achieving environmental control. LODEM presents architects and facility specifiers with the information, standard, and industry leading manufacturers to ensure that their facilities meet the necessary regulatory standards and maintain environmental control at the loading dock.

For more information about this topic, register for LODEM’s webinar on May 10th, 2023 here: https://attendee.gotowebinar.com/register/4492045289762859614

For more information about LODEM, please visit their site: https://www.mhi.org/lodem