How Proper Lighting Increases Productivity And Employee Wellbeing

Ergonomics is most often associated with physical tasks, with many operations recognizing that repetitive, manual motions or improper lifting of heavy objects can cause worker injuries. Yet lighting — ambient, overhead, natural, and task — is a significant contributor to worker eye strain, which can increase fatigue and impede productivity. An environment that is too dark, or where large objects obstruct light and create shadows, can create trip hazards. An extremely bright environment can cause headaches, as can digital devices with screens that are not properly calibrated. An assembly process at a workstation that isn’t properly illuminated can slow down an operator struggling to see what they’re doing, increasing the risk of a mistake.

To avoid these ergonomic lighting mistakes, it’s important to closely review the current work environment to identify and remedy such problems. The following recommendations shed some light on how to properly illuminate different areas within a warehouse, distribution center, fulfillment center, or manufacturing facility.

- Light from screens and other devices. Workers interfacing with monitors on computers, tablets or hand-held devices should be able to clearly distinguish the displayed information. It’s important to properly calibrate these screens to provide adequate contrast and resolution for legibility. Text and images should be crisp and easy to read; not pixelated or fuzzy. Additionally, device screens can be too bright or too dim. Ensure that each is properly set for the environment in which it is to be used. Further, monitors or screens used at a workstation should not be surrounded by bright task lights, which can cause glare. Neither should they be placed in front of a window, also to avoid glare.

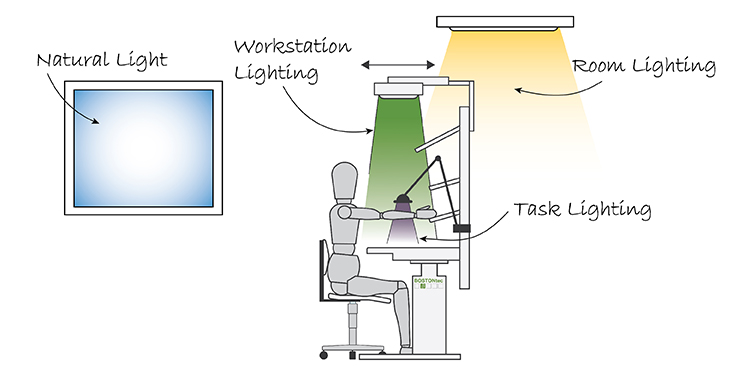

- Workstation task lighting. Proper placement of task lighting is critical to ensure both productivity and accuracy. There are many ways to create a well-lit workstation, and the correct lighting accessories depend on the task. On a packaging station proper illumination can be placed above the operator to light the entire work surface and supplies. For assembly processes a focused task light might be required to provide greater visibility of parts and tools. Highly detailed work, such as that performed in the electronics industry, may also require magnification along with task lighting to both improve accuracy and make the process easier to see.

- Overhead and ambient lighting. Not every facility has skylights or windows providing natural light (although, as a supplement to overhead lights, those can significantly improve visibility in storage and picking aisles during daylight hours). For those relying solely on overhead lighting to illuminate the building, it’s important to pay attention to both the color temperature and the intensity of the lighting.

- Color temperature refers to the amount of yellow (warm) or blue (cool) produced by the lighting. Warm lighting is typically found in a home as it creates a cozier, more relaxed feel. Cool lighting is more commonly used in retail, industrial, offices and other workplaces as it tends to enhance alertness. Lighting that is excessively blue, or cool, should be avoided as it can create an environment that feels harsh and potentially unpleasant.

- Intensity refers to the amount of visible light the lighting produces. Task lighting tends to be more intense to increase visibility; the intensity of overhead or ambient lighting should be balanced to achieve an evenly lit environment that avoids strong contrasts between lighter and darker areas.

Operations seeking to optimize their lighting to ensure proper visual ergonomics for their workforce don’t have to go it alone. There are ergonomic lighting specialists, including members of MHI’s Ergonomic Assist Systems & Equipment (EASE) Industry Group, who are available to assess a facility’s current illumination setup and make recommendations for areas of improvement.

Looking for other ways to help determine if your operation is following ergonomic best practices? EASE offers a variety of checklists on their website.