Protect Personnel, Prevent Product Falls And Secure Stored Contents With Rack Guarding

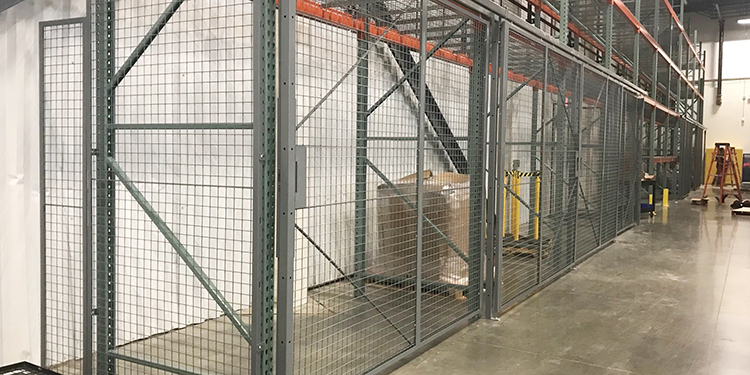

Operations seeking to secure the contents of their industrial steel storage rack have a wide range of steel mesh containment panel options available. These panels can be attached to the uprights on the sides and back of individual rack bays, used to block access to an aisle, or configured to form a secure perimeter around an entire rack structure — with secured access gates or doors sized for personnel or forklift access.

Also referred to as rack back, rack safety panels, or rack guarding, the panels are often used to secure high-value items, to prevent pallets or products from falling off the sides or back of a pallet rack and potentially striking a worker, or to limit personnel access to content stored in the rack. They can also be deployed to guard automated systems used within the racking, such as automated storage and retrieval systems (AS/RS) including cranes and shuttles.

Steel mesh containment panels typically come in standard heights of 4 or 5 feet, and widths in 1-foot increments up to 12 feet. During installation, the panels are vertically mounted edge-to-edge to create heights of eight to 10 feet (or more). Restricting a standard panel size to a maximum of 5 x 12 feet makes them easier to handle, ship, install, remove and replace. Custom-sized panels can also be created but can be more expensive than those built to standard dimensions.

Other rack guarding specification choices include:

Mesh Opening Size – The most common options are a 2-inch square, a 1.5-inch diamond, or a 1 x 2-inch horizontal rectangle. For more security a smaller mesh opening — or tighter weave — can be selected; this uses more material, adding weight and rigidity to the panel.

Mesh Material – 10-gauge welded wire is the standard used by most steel mesh containment panel manufacturers. As a general rule of thumb, 10-gauge wire panels are used for cases of product weighing less than 40 pounds. For panels installed around heavier products, in racks that are accessed more frequently by forklifts, or in more abusive environments, heavier 6-gauge welded wire is often recommended for enhanced durability.

Mounting Brackets – provide necessary panel offsets to allow for large and odd shape unit loads to overhang the back side of the rack. Bracket offsets start with flush mount and extend out to 12” offsets. The most common offset bracket are 4” or 6” panel offsets.

Although they are available as a retrofit for an existing rack system, the optimal and most cost-effective time to specify steel mesh containment panels is during the initial design phase. This ensures that the system will account for obstacles such as conduit, sprinkler heads, electrical outlets, or obstructions such as building columns.

Want more information about securing your storage rack? The members of the Protective Guarding Manufacturers Association (ProGMA), recently published a new standard, “ANSI MH31.1-2019 – Steel Mesh Containment Panels Used In Vertical Storage System Applications: Performance and Testing Requirements,” that will be released at MODEX 2020 and available for purchase.