Three Steps To Successfully Gain Upper Management’s Support For An Ergonomic Initiative

Congratulations! You’ve recently been tasked by upper management to implement an industrial ergonomic initiative within your company. But just because the top brass says they want to invest in creating a more ergonomic work environment doesn’t mean they have a full grasp of what that could entail. To ensure both full support from company leadership and a successful ergonomic initiative, follow these three steps.

1. Establish a scope. One of the first questions to ask is whether there is an established budget, or if will you be tasked with proposing the budget. If you have a budget, you can perform your due diligence and prioritize. However, if it is incumbent upon you to provide the budget, you need to understand how these purchases will benefit the workforce and will deliver a return on investment (ROI) for your company. In many cases the budget upper management expects to allocate is not in line with what is truly needed to create an ergonomic facility. Additionally, it is important to understand the expectations for project completion.

2. Educate. Sharing some of the following broad statistics can help you start your ROI assessment, as well as make raise managements’ awareness of the financial impact of poor ergonomic environments:

- Companies spend $94 billion collectively on workers’ compensation claims on an annual basis.

- Material handling and poor ergonomics represents 32% of all workers’ compensation claims.

- Today, the average worker in the industrial sector is 46 years old — versus 28 years old in 1970.

- There are more than 380,000 cases of ergonomic injuries with missed days worked per year.

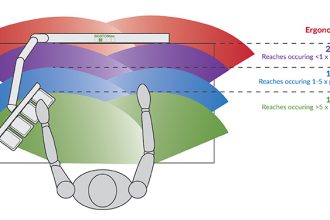

It is important that upper management gain a fundamental understating of the core ergonomic issues that contribute to these costs. Ergonomic strains within an industrial facility are a result of daily pushing, pulling, carrying, twisting, lifting, lowering, bending, holding, stacking, and squatting. The systems you implement, the guidelines you establish, and the equipment you procure will be specific to those stressors. You should be provided the ability to research a variety of systems in order to properly alleviate high risk material handling.

3. Collaborate. The success of the implementation is also crucially dependent on having access to other resources and team members. Gain buy-in from those who will be directly impacted by the initiative and keep them involved in the decision-making process and implementation timeline. You will need these resources to help see the project through successfully to completion. A sound ergonomic plan will help an aging workforce and provide tangible ROI that is required for such capital expenditures.

The members of the Ergonomic Assist Systems & Equipment (EASE) Industry Group of MHI offer a variety of free resources to help support an industrial ergonomic initiative. The complete library is available here.