New Research Examines Biomechanical Efficacy and Factors Affecting the Adoption of Ergonomic Equipment

While the benefits of implementing ergonomic equipment are well documented, the reasons why workers do not always use such equipment are less so. To assess existing research on these topics, the members of the Ergonomic Assist Systems & Equipment (EASE) Council engaged Steven Lavender, PhD, CPE, and his graduate student Eyad Mirdad, MS. Both are affiliated with The Ohio State University’s College of Engineering, where Lavender is a Professor of Integrated Systems Engineering and of Orthopedics. Their research examines the biomechanical efficacy and factors affecting the adoption of ergonomic equipment. A new paper, entitled “Manipulators and Work Positioners Used in Manual Material Handling Tasks: Their Biomechanical Efficacy and Factors Affecting Their Adoption,” is available via the EASE Council website.

Ergonomic Equipment Research on Focused on Manipulators and Work Positioners

“There are many studies that demonstrate the relationship between manual material handling tasks performed in an industrial environment and the high risk of musculoskeletal injuries,” explained Lavender. “The EASE Council commissioned us to review existing studies of different material handling assistive devices in industrial settings. We specifically focused on prior research that documented biomechanical and performance measures surrounding the use of ergonomic assistive devices.”

The intent, continued Lavender, was partially to identify research gaps for future studies. The findings can also help those designing work processes, as well as affected workers, improve adoption rates.

Lavender and Mirdad focused their research on ergonomic equipment that helps workers perform manual handling tasks by reducing a portion (but not all) of their workload. These include:

- Manipulators, such as lift assist devices, articulated arms, and hoists; and

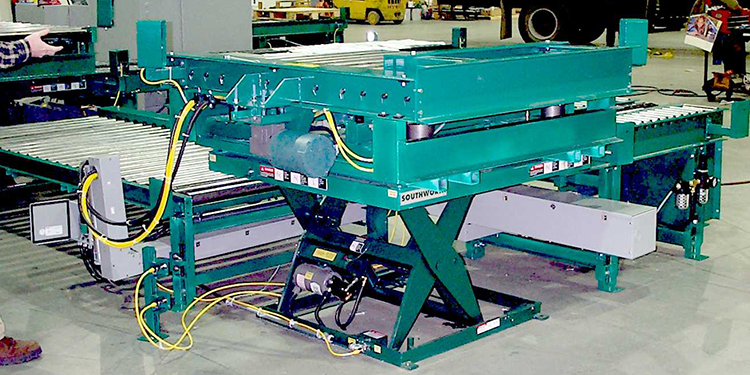

- Work positioners, including tilters and lift tables.

Findings Surrounding Manipulators

Manipulators are usually overhead and suspended above the work area, said Lavender. “They reduce or eliminate the weight of a load as workers lift and lower it. They’re typically used for transfer of moderate to heavy weight materials in assembly operations or when palletizing or depalletizing materials.”

The research team reviewed 10 different studies associated with manipulators. The majority of those research projects focused on objectively measuring physical exertions associated with these types of tasks. Measurements included applied forces, duration, postures, movement speeds, and amount of muscular effort required.

All reviewed studies investigating manipulator usage documented reduced biomechanical loads. “Some of the studies we reviewed also assessed the impact of manipulators on worker performance,” Lavender noted. “Overall, studies found that manipulators can minimally increase movement time, distance, and task duration.”

That increase in time may partially explain why some employees are reluctant to embrace ergonomic assistive equipment. However, Lavender points out that with increased use, workers are likely to become more familiar with manipulators and therefore faster when using them.

“Likewise, a small increase in handling time with a manipulator may not affect overall performance if it reduces fatigue,” he continued. “Workers who are less tired perform more efficiently. They also tend to need fewer breaks compared to those performing manual tasks without ergonomic equipment.”

Work Positioner Findings

Positioner devices enable workers to adjust the height and/or location of a lifting task, thereby reducing the effort needed to reach, pick, or place an item.

“Much of the existing research on work positioners focuses on picking from a container that sits on either a stationary or cart-based adjustable height lifter,” Lavender said. “Some of the ergonomic equipment evaluated includes a turntable top to allow rotation of the content closer to the worker.”

The researchers found seven different studies assessing different types of work positioners. These included pallet lifts, pallet tilters, height-adjustable mobile carts, and self-leveling turntable lifters.

“Overall, these assessments found that the ergonomic equipment decreased spinal loads and reduced the risk of lower back injuries,” Lavender reported. “Those that measured productivity also documented improvements when compared to unassisted manual material handling processes.”

Encouraging Adoption of Ergonomic Equipment

Despite reducing the risk of musculoskeletal injuries, some workers do not utilize available ergonomic equipment such as manipulators and positioners. The authors reported that there are very few papers that consider factors affecting the adoption of ergonomic assist devices in industrial settings.

However, the authors found several studies focused on factors surrounding ergonomic assist equipment in healthcare settings for patient handling. They insist that the “Insights from those studies are applicable to industrial material handling situations.”

Barriers to adoption of ergonomic equipment, according to the authors, exist both for individual users and for organizations. Among the reasons individual workers may avoid using manipulators and work positioners are fear the devices will slow them down, resistance to change, or unwillingness to spend time learning how to use them effectively.

At the organizational level, many organizations have weak management support, fail to conduct awareness training for their workforce as interventions are introduced, and/or do not engage their workforce in any sort of participatory ergonomics programs that would ensure worker buy-in early in the implantation process.

“To overcome these barriers to ergonomic equipment adoption, it’s important that the organization educate workers through strong, positive communication,” Lavender advised. “It’s also key to involve ergonomists throughout the implementation and training phase. Further, involving workers in the evaluation and selection process when considering ergonomic equipment encourages adoption among their colleagues.”

Want to learn more about the biomechanical efficacy of ergonomic equipment and the factors affecting its adoption? The full report is available for download via the EASE Council website.