Warehouses, distribution centers, and manufacturing facilities often rely on people power to move loads. Workers push or pull wheeled carts and pallet jacks to transport items. Yet the forces associated with maneuvering parts and products through different processes can also increase the risk of back and shoulder injuries. To help, an online tool offers pushing and pulling guidelines that operations can use to assess their workers’ potential injury risks.

The Ohio State University Spine Research Institute (SRI) developed the tool for the Ohio Bureau of Worker’s Compensation (BWC), explained Dr. Gary Allread, SRI Program Director.

“It’s offered as a free resource that anyone has access to,” he said. “Companies can use it to examine how their current pushing and pulling requirements compare to safe limits for these forces. They can also use this ergo tool to evaluate how adjustments to those parameters will reduce injury risks.”

Hosted by the Ohio BWC, the site is at: bwc.ohio.gov/employer/programs/safety/PushPullGuide/PushPullGuide.aspx It specifically supports evaluation of four common pushing and pulling activities:

- Straight-line movements

- Turns

- One- or two-handed pulling

- Two-handed pushing

Research Led to Objectively Determine Guidelines

There are other pushing and pulling guidelines available, noted Allread. Most, however, are based on what he called psychophysical experiments. These investigations asked test subjects to report how much effort they felt safe exerting when pushing or pulling a load.

“The issue is that a back or shoulder injury often results from the cumulative effect of multiple damage incidents,” he explained. “So what may feel safe at the time may actually have resulted in physical damage, such as a small tear to the surface of a disc is the back, for example. Our bodies do not have the ability to feel when these types of injuries occur. It’s not until enough damage has occurred that a nerve is impacted, and that’s when we’ll experience pain.”

For that reason, Allread and his team of researchers collected data from more than 60 different company facilities, to determine the various ways in which employees push and pull objects. “Based on that robust sample, we were able to accurately simulate those in our lab. From this, we were able to objectively determine what push/pull conditions placed unacceptably high biomechanical loads on the spine.”

The pushing and pulling guidelines are based on an analysis of the mechanics of those movements. “We’re using a validated model that evaluates the stress on the discs resulting from different levels of force,” continued Allread. “When data input into the online tool produces a yellow or red result, that indicates — based on our model — that workers are damaging their backs, even though they don’t feel it.”

Adding Measurements to the Pushing and Pulling Guidelines

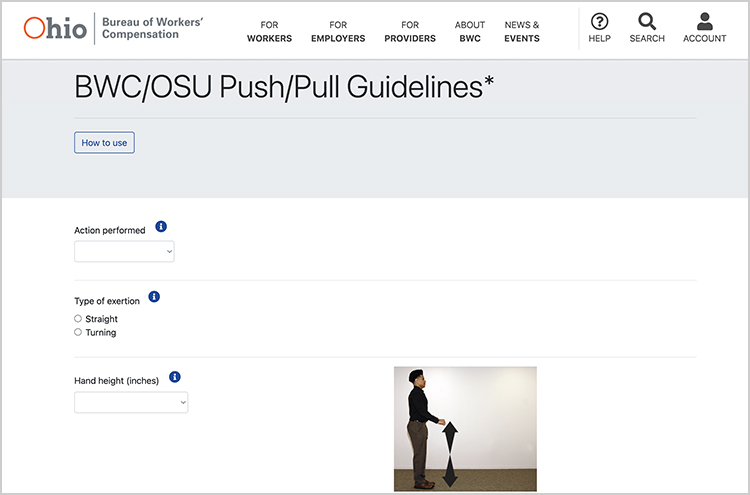

To assess a current pushing or pulling motion, users input a short series of data into the online tool’s fields. These include:

- A measurement — in pounds — of the maximum push or pull force needed to initiate the movement. Determining this requires a force gauge. The highest measurement is usually the force required to start the motion.

- The distance from the floor to the height of the hands as individuals typically move the object. Height measurements range from 32 to 48 inches in 1-inch increments.

- When assessing push or pull forces associated with turns, the tool also requires a measurement of the space between the hands. These widths range from 12 to 36 inches in 1-inch increments.

After submitting the data, a pop-up window displays the assessment. It shares three results indicated on the green, yellow, or red segments of a horizontal bar.

- Tasks falling in the green range are safe for at least 80% of the population.

- Tasks yielding a yellow result are safe for 50-80% of the population. The guidelines suggest making changes to make the task safer for more people.

- Tasks landing in the red segment are safe for less than 50% of the population. The guidelines strongly recommend changes to reduce the risk of injuries.

By modifying the handle to a higher height, for example, a worker will stand more upright. That gives them more strength to push or pull the load, explained Allread. “Or, a load that is pulled with one hand and found to be risky may actually be safe if it is instead pushed with two hands,” he said.

Recommendations for Workplace Design

A companion document detailing the researchers’ methodology accompanies the pushing and pulling guidelines tool. It includes tables that outline the green, yellow, or red force limits for each action and across the different hand heights. The document also shares the research team’s key recommendations for workplace design. These include:

- Higher handle heights generally reduce pushing and pulling exertions.

- Avoiding turning pushes or pulls, which subject workers to higher biomechanical loads than straight line maneuvers.

- Two-handed turning has a lower risk of injury than one-handed turning.

Tool Continuously Improved, Expanded

The pushing and pulling guidelines are an ongoing work in progress, added Allread.

Now that the guidelines are in use, the researchers are accepting user feedback to expand its parameters. The goal is to continuously improve the resource and grow its applicability to industrial scenarios. Future additions include pushing and pulling limits for stopping a load in motion and for traversing inclines and declines.

“We expect to have the latest updates available within the next year or so,” Allread concluded.

Find Ergonomic Solutions from EASE Council Members

Looking for ergonomic material handling equipment that can help your operation meet these pushing and pulling guidelines? Check out the Ergonomic Assist Systems & Equipment (EASE) Council of MHI. The EASE Council offers a broad range of educational resources on its website. These include presentations and seminars, technical papers, checklists, and ergonomic articles. Further, its members are available to consult, answer questions, and offer advice on ergonomics best practices and safe equipment use.