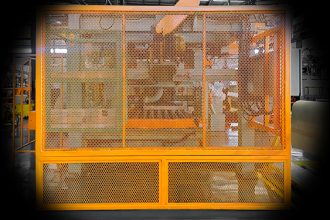

Storing products overhead in pallet racking is a great way to maximize the usable space in a warehouse or distribution center (DC). Yet it also increases the risk of items falling into aisleways and potentially causing injury to workers or damage to equipment. Attaching steel mesh containment panels to the uprights, backs, and sides of pallet rack is one way to protect personnel, products, and property. To help end users compare different panels, the members of the Protective Guarding Manufacturers Association (ProGMA) developed American National Standards Institute ANSI MH31.1. Recently released, a new ProGMA video explains the steel mesh containment panel standard.

About the Steel Mesh Containment Panel Standard

The video shares the highlights of ANSI MH31.1 – Steel Mesh Containment Panels Used In Vertical Storage System Applications: Performance and Testing Requirements. The standard includes guidance and information about design, operating, and testing practices. It also details performance criteria and operational requirements. It is available for purchase via ProGMA’s website: mhi.org/progma.

Prior to ANSI 31.1, no steel mesh containment panel standard existed. That meant owners, users, designers, purchasers, or specifiers of these products — also known as rack safety panels, rack guarding, and rack back — had no benchmark for assessing their safety and reliability. While many manufacturers tested their products, there was no uniform methodology for them to follow as a means to verify panel quality, consistency, and durability. That made it difficult for purchasers to assess different options.

ANSI MH31.1 Testing Process Explained

The ANSI MH31.1 steel mesh containment panel standard details parameters for product testing. The procedure simulates a pallet rack with a steel mesh panel of specific dimensions installed. A pendulum weighted to create an impact force of 350-foot-pounds (475 joules) strikes the panel at least twice. The impacts target the panel in both the center and a corner.

The pendulum tests determine two things:

- The amount of deflection caused by the impact. This quantifies the degree of mesh displacement.

- The amount of deformation resulting from the strike. This evaluates any changes in the shape of the mesh.

Test results indicate the likelihood of one (or more) of the following occurring in an actual installation should an impact occur:

- Deflection to a degree that causes the mesh panel to encroach into an aisle or to contact a panel mounted to a pallet rack behind it.

- Permanent wire mesh deformation.

- Fastener hardware or brackets breaking away from the panel or rack.

- Broken wire mesh welds.

The video also explains that the steel mesh containment panel standard provides insights for compliance with flue spacing requirements. These requirements, from the National Fire Protection Association’s NFPA 13, Standard for the Installation of Sprinkler Systems, mandate a horizontal gap between the back sides of back-to-back rack and shelving systems.

Need More Protective Guarding Help?

In addition to the video and the steel mesh containment panel standard, several members of ProGMA manufacture these solutions. They are available to answer questions about the selection and application of these panels. Learn more about the ANSI MH31.1 standard and key considerations when specifying these rack accessories, here.