Safeguard Personnel And Pallet Rack With Protective Guarding Solutions

Walk into virtually any warehouse or distribution center and you’ll see pallet rack—rows upon rows of it. Industrial steel storage rack creates dense vertical storage, allowing an operation to maximize its overhead space to hold pallets of inventory for order fulfillment. The design and engineering of each system matches the application’s required load capacity, the types of forklifts used, as well as any other seismic, fire, and building code requirements applicable in the facility’s region. This ensures the system is structurally sound and can safely support the loads placed within it. But there are still areas within and around pallet rack that can pose safety concerns, both to the rack itself and to personnel working near or in the system. That’s why it’s important to safeguard personnel and pallet rack with protective guarding solutions.

Pallet rack beams and uprights can be vulnerable to damage from forklift impacts. Falling product from upper levels can pose a potential injury risk to personnel. Workers stationed in pallet rack-based pick modules are at an increased risk of falling through unprotected openings. For all of these reasons, there are a variety of protective guarding solutions available for attachment to—or around—a pallet rack installation to help reduce the risk of damage and injury.

Identify Risks with a Protective Guarding Checklist

The members of the Protective Guarding Manufacturers Association (ProGMA) have published a Protective Guarding Checklist to help users identify risks throughout their facilities, including pallet rack. The checklist also features a variety of protective guarding solutions specifically designed for use with industrial steel storage rack, such as:

Devices that protect rack columns from impacts at the ends of an aisle where traffic is highest, and forklifts frequently turn corners. Mounted a short distance away from each racking row’s end to shield the structure from contact, these include bollards, industrial facility protection guardrail, and kerbing/bumpers. Along the rack aisles, rack leg protectors can be mounted to the floor in front of rack columns or attached directly to the uprights to deflect impacts and reduce the risk of damage.

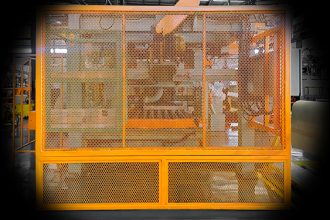

Devices that protect rack columns from impacts at the ends of an aisle where traffic is highest, and forklifts frequently turn corners. Mounted a short distance away from each racking row’s end to shield the structure from contact, these include bollards, industrial facility protection guardrail, and kerbing/bumpers. Along the rack aisles, rack leg protectors can be mounted to the floor in front of rack columns or attached directly to the uprights to deflect impacts and reduce the risk of damage.- Equipment for product containment within pallet rack includes flexible safety netting and rigid steel mesh panels, both of which are attached to the rack structure itself. Should a product fall off a pallet, these systems prevent it from reaching the floor.

- To protect workers from falls off elevated, rack-supported pick modules and work platforms industrial pedestrian guardrails are installed around the perimeter of the work area. Kickplates mounted at the edge of these elevated platforms provide additional item containment by preventing items from rolling off. Also, to secure access openings on elevated pick modules, safety gates, pallet drop gates, and pallet flow gates are available.

Install Protective Guarding Solutions on Existing Pallet Rack

“The optimal and most cost-effective time to specify any of these protective guarding solutions for a pallet rack is during the initial design phase,” said Aaron Conway, President of ProGMA member Mezzanine Safeti-Gates. “However, they are all available post-installation as retrofit components for an existing rack system.”

For operations seeking to enhance the safety of both personnel and racking structures, Conway recommended walking through the facility’s pallet rack with a professional. “Whether it’s the manufacturer, the systems integrator, the rack dealer or distributor, an independent safety consultant, a member of ProGMA, or a member of the Rack Manufacturers Institute (RMI), an outside expert can help to identify areas with the highest potential hazards,” he said.

Regular Visual Inspections Are Critical

Additionally, it’s a best safety practice for managers or supervisors to conduct regular visual inspections of the pallet rack system and associated protective guarding solutions to identify signs of damage. Further, train all associates to promptly report any impacts or fallen product.

“If there’s an area where damage routinely appears, or where product frequently falls, those areas would benefit from adding a protective guarding solution,” Conway explained. He further advised inspecting the areas with the highest traffic or most frequent product turnover the most often, as there is a greater likelihood of an impact or falling product.

“It’s also a good idea to look for areas where the facility layout or process flow has changed,” he continued. “For example, if a new piece of production equipment has been installed that’s altered the traffic pattern and caused forklifts to drive much closer to racks—or where product falling off rack might cause damage to that new machinery—those are areas where protective guarding solutions should be added.”

That said, not every row of rack needs guarding, nor does one type of guarding solve every problem, he said. “Areas where there is very little traffic, or slower moving products, may not need any guarding at all. Or areas only visited by smaller powered pallet jacks won’t need as much protection as those where larger forklifts move in and out throughout every shift.”

Standards Provide Protective Guarding Guidelines

For operations looking for additional guidelines on the installation and use of guardrails for elevated pick modules within pallet rack, Conway points to two separate RMI publications: RMI’s ANSI MH16.1: Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks and ANSI MH32.1: Stairs, Ladders, and Open-Edge Guards for Use with Material Handling Structures, which RMI developed in partnership with the Storage Manufacturers Association (SMA).

“All of the Industry Groups of MHI focus on producing standards for material handling equipment that enhance the safety of an operation,” concluded Conway. “There are great resources available to help facility owners make sure their equipment and personnel remain safe and protected at work.”

Want more ideas about the types of protective guarding solutions available to safeguard your pallet rack and the personnel working in and around it? In addition to the Protective Guarding Checklist, the members of the Protective Guarding Manufacturers Association (ProGMA) curate a Protective Guarding Search Tool, a comprehensive listing of nearly 40 different solutions to make an operation safer.