Applying Safety Netting? Avoid These Common Mistakes

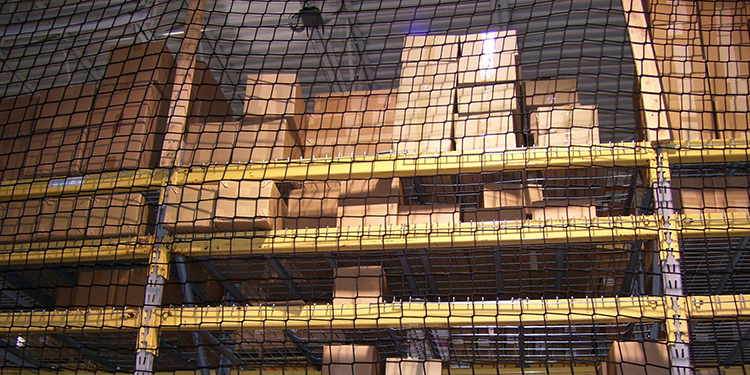

Safety netting plays a critical role in keeping people, products, and operations safe within dynamic warehouse environments. Made of woven synthetic fibers, these protective guarding solutions create a barrier that prevents products from falling to the floor below. However, even the best safety netting solutions can fall short if they’re applied incorrectly.

“Safety netting should be a precision tool in your risk-control arsenal,” said Tammy Raymond, Marketing Director at InCord. The company is a member of the Protective Guarding Manufacturers Association (ProGMA). “When correctly applied, it safeguards your people and your product—without disrupting your processes.”

The following explores four common mistakes made when implementing safety netting in warehousing and industrial applications. It also details how to fix them.

Mistake # 1: Guarding and Picking from the Same Rack Face

One common misstep occurs when an operation attempts to protect stored inventory that is also accessed from the same side of the rack. This dual requirement—guarding and picking—can create a conflict when using the wrong type of netting, said Raymond.

“Standard fixed netting solutions may block easy access to products. That often results in operations not even attempting to apply protective netting,” she noted. “Not doing so, however, undermines both safety and efficiency.”

These applications are ideal for roll-up safety netting solutions, continued Raymond. Functioning similarly to a vertical window blind, these nets offer both protection and access. They are easy to lower to secure inventory when it’s not needed. Conversely, raising the nets allows access during picking operations.

“Selecting a netting solution that delivers both protection and workflow flexibility is key to preventing downtime,” Raymond explained.

Mistake # 2: Using Standard Netting on Conveyor Systems

Another frequent issue occurs around conveyor systems. These areas require frequent access for retrieving dropped items or clearing jams. Yet, when standard netting is used here, workers may cut it open to gain access. They then reattach the net with zip ties or similar makeshift repairs.

“Over time, these quick fixes compromise the safety netting’s integrity and reduce its effectiveness,” said Raymond.

Instead, facilities should use high-cycle access netting designed specifically for frequent entry, she advised. “Options with zippers or Velcro closures allow safe, easy access without damaging the structure of the netting.”

Mistake # 3: Overlooking Horizontal Netting in Picking Zones

Pushback racks and picking aisles often create horizontal drop zones where inventory or equipment can fall from above. Some facilities use steel guarding below these areas. However, steel is rigid and can damage falling products. It’s also a more expensive solution that can pose handling challenges during installation or maintenance.

Horizontal safety netting provides a more forgiving, flexible solution. It offers reliable protection against falling items with a soft catch that minimizes damage to product. It’s also often easier to install and maintain than steel options.

Mistake # 4: Gaps in Elevated Platform Edge Protection

Mezzanines, pick modules, and elevated work platforms used for inventory storage often present hidden fall risks. This is especially true near open edges or railing gaps. In many cases, these hazards go unnoticed until an incident occurs. If gaps exist in the railing—or if inventory is stacked higher than the guardrail—there’s a risk of product falling to the level below.

The fix is to use netting designed specifically for mezzanine applications. These systems can fill railing gaps and extend above the top rail to contain over-height inventory, ensuring full perimeter protection.

Assess Individual Zones for Optimal Safety Netting Application

Ultimately, taking a blanket approach to installing safety netting across different warehouse zones can be a costly mistake.

“No two areas of a facility are exactly alike. What works for one zone may not be appropriate for another,” Raymond said. “One misapplication can compromise both safety and productivity.”

Variables include inventory size, movement frequency, rack structure, and workflow demand. That makes customization essential. Raymond advised conducting a zone-by-zone fall protection assessment. Facility managers should evaluate how inventory moves through each area, what type of access is needed, and which risks are present. With this information, they can specify the appropriate netting solution for each scenario.

“Effective safety isn’t just about using netting—it’s about applying the right netting in the right place,” noted Raymond. “Several ProGMA members offer safety netting, and all are available to consult and help guide the selection process.”

Learn More About Safety Netting

Looking for more ways safety netting can enhance personnel safety? Visit Overhead Mesh Guarding, Safety Netting, and Conveyor Guarding in ProGMA’s Protective Guarding Search Tool for examples and suppliers.