Improve Operational Safety With Protective Guarding Resources From The ProGMA Toolbox

Navigating the breadth of options to find the optimal protective guarding solution for a unique application can be challenging. Particularly when seeking equipment that ensures compliance with Occupational Health and Safety Administration (OSHA) regulations. Recognizing this, the members of the Protective Guarding Manufacturers Association (ProGMA) have assembled a toolbox of protective guarding resources. These resources help facility owners seeking to improve operational safety in warehouses, distribution centers, and manufacturing facilities.

Navigating the breadth of options to find the optimal protective guarding solution for a unique application can be challenging. Particularly when seeking equipment that ensures compliance with Occupational Health and Safety Administration (OSHA) regulations. Recognizing this, the members of the Protective Guarding Manufacturers Association (ProGMA) have assembled a toolbox of protective guarding resources. These resources help facility owners seeking to improve operational safety in warehouses, distribution centers, and manufacturing facilities.

Whether it’s safeguarding employees from equipment, vehicles, falls, or falling item hazards, or protecting inventory and facility structures from damage, there are plenty of opportunities to improve operational safety. That’s why, in a recent MHIcast episode, ProGMA’s leadership detailed several protective guarding resources the organization makes available via its website.

The podcast featured Chair Ray Niemeyer, Vice President of Sales and Marketing at SpaceGuard Products, and Vice Chair Ken Parrott, Product Manager at Impact Recovery Systems. Both of their companies are ProGMA members. The pair explained how each tool helps prospective buyers of protective guarding equipment quickly learn about — and find — solutions.

Videos Illustrate Protective Guarding Equipment in Action

If a picture is worth 1,000 words, a video is worth at least ten times that much because it shows a product in action. This was the reason behind ProGMA’s development of several different videos that show different types of protective guarding in use, explained Parrott.

If a picture is worth 1,000 words, a video is worth at least ten times that much because it shows a product in action. This was the reason behind ProGMA’s development of several different videos that show different types of protective guarding in use, explained Parrott.

“People in general find videos more engaging. That’s certainly been the case with the videos ProGMA has produced,” he said. “Because they’re animations, we are able to depict accidents that are preventable with the use of different protective guarding solutions. They’re a little campy, but they reinforce the point.”

Additionally, the videos — which are also available on ProGMA’s YouTube channel — are easy to share. This helps facility owners, operations managers, and safety directors gain a better understanding of different protective guarding solutions and how to properly apply them.

“The videos also show guarding technologies integrated with other material handling equipment and systems,” Niemeyer added. “It’s easy to see how the protective guarding interacts with many commonly used solutions in warehousing and manufacturing.”

Search Tool Enables Quick Visual Search of Potential Solutions

Intended to be a one-stop resource for operations managers, safety managers, and facility owners, ProGMA’s Protective Guarding Search Tool covers a wide range of products. In addition to listing multiple solutions, each category shares comprehensive explanations for equipment use and example application images.

Intended to be a one-stop resource for operations managers, safety managers, and facility owners, ProGMA’s Protective Guarding Search Tool covers a wide range of products. In addition to listing multiple solutions, each category shares comprehensive explanations for equipment use and example application images.

“We created the search tool based on feedback from the customers of ProGMA members. They wanted an easier way to find different protective guarding options and manufacturers,” said Niemeyer.

The challenge many end users face is that multiple protective guarding solutions can work in many different areas of a warehouse or factory, Parrott noted. “Searching from a product focused point of view may not show all the different options available to protect a unique application,” he said.

Recently updated with the addition of more product categories, the Protective Guarding Search Tool on ProGMA’s website lists nearly 40 different types of equipment options. A search function allows users to type in the keyword to describe what the guarding will protect. For instance, search terms might include machinery, conveyor, loading dock, building columns, pallet rack, or industrial work platforms. Results share product descriptions, images, and manufacturers.

“By using the tool to search based on the application, a diverse range of protective guarding options appears,” Parrott said. “So whether you need to protect rack, a doorway, or a robotic cell, for example, the tool will quickly display the different types of protective guarding equipment that would work.”

Case Studies Detail Successful Protective Guarding Applications

Another protective guarding resource offered by ProGMA on its website is a curated list of case studies. Provided by ProGMA members, these short form stories detail customer applications of different protective guarding equipment. The case studies quickly recap the operation’s challenge, the solution deployed, and the results.

“The case studies make it easier for operations managers to understand that their facility is not the only one facing a specific guarding problem,” Niemeyer said. He added that the case studies are also a good resource for ideas about areas within a facility that might benefit from the addition of protective guarding.

“For example, a lot of companies are looking to expand their operations by using the open-air space in their facilities. To do that, they’re installing mezzanines, also known as work platforms,” he continued. “That introduces several new areas that require adequate protection of the structure, the edges, and drop zones. There are several case studies on the ProGMA website that detail how operations used protective guarding to meet OSHA requirements.”

ANSI Standards Establish Testing Protocols for Easier Product Comparisons

One of the most important protective guarding resources ProGMA members produce are American National Standards Institute (ANSI) standards. These documents provide guidance and information about the design, operating, and testing requirements of different protective guarding systems. Currently there are two ANSI standards available from ProGMA:

ANSI MH31.1 – Steel Mesh Containment Panels Used In Vertical Storage System Applications: Performance and Testing Requirements

This standard details the performance criteria and operational requirements for steel mesh containment panels. The recommended testing process it outlines creates a uniform procedure for determining the amount of deflection and deformation caused by an impact load striking the mesh.

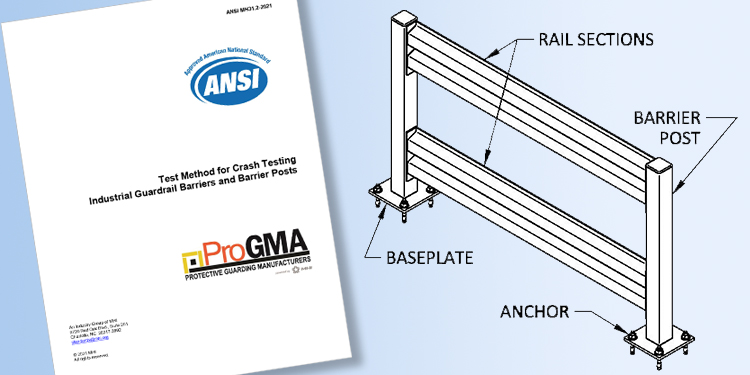

ANSI MH31.2 – Test Method for Crash Testing Industrial Guardrail Barriers and Barrier Posts

This standard offers a consistent testing methodology to assess the performance of industrial guardrails and barriers that safeguard pedestrians and equipment against motorized vehicle and forklift impacts. For prospective buyers of these solutions, the standard makes it much easier to compare protection options.

“Prior to the creation of these two standards, there was no consistency among manufacturers in product testing,” explained Parrott. “This helps an end user more easily compare apples to apples.”

Niemeyer agreed. “Not every company is following these ANSI standards. But any buyer considering a product made by a ProGMA member can be assured they are.”

Find More Protective Guarding Resources

Looking for more ways to improve operational safety with protective guarding resources from the ProGMA toolbox? Listen to the full podcast. Then, reach out to the members of the Protective Guarding Manufacturers Association (ProGMA) for guidance and recommendations.