ProGMA’s Two MODEX 2024 Educational Sessions Explore The Latest Protective Guarding Technologies

Among the Top 10 causes of serious, disabling workplace injuries are falls to a lower level, falling items, being caught in machinery, and pedestrian/vehicle incidents. Together, these four causes alone cost employers $15.79 billion, according to the 2023 Liberty Mutual Workplace Safety Index. Manufacturing and distribution operations can reduce the risk of these costly injuries by applying protective guarding to help keep workers safe. But there are a lot of available solutions. To help operations safety managers understand their options, the Protective Guarding Manufacturers Association (ProGMA) will present two MODEX educational sessions that explore the latest protective guarding technologies.

Two ProGMA Sessions Highlight Guarding Solutions

Members of ProGMA will present two separate education sessions. Each will highlight a variety of protective guarding technologies:

- “Ensuring Operational Safety and Efficiency: Strategies for Safeguarding Industrial Storage Systems” is on Monday, March 11, from 3:00 – 3:45 p.m. Eastern time in Theater G on the right-hand wall of Hall B.

- “Evolution of Safety” is on Wednesday, March 13, from 2:30 – 3:15 p.m. Eastern time in Theater G on the right-hand wall of Hall B.

Registration for the entire event — including all education seminars — is free. Those who are unable to attend the ProGMA education sessions in person can catch them later online. Both presentations and their audio recordings will be viewable via the show website after MODEX concludes.

Multiple Protective Guarding Solutions for Storage Systems

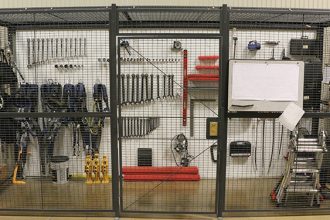

Ray Niemeyer, Vice President of Sales at ProGMA member SpaceGuard Products, will present “Ensuring Operational Safety and Efficiency: Strategies for Safeguarding Industrial Storage Systems.” He noted that companies spend millions of dollars deploying racks, work platforms, rack-supported mezzanines, automated storage and retrieval systems (ASRS), and more. Yet many fail to install protective guarding in and around them. These include netting or steel mesh containment panels, column guards, industrial guardrails, and more.

“There’s a broad variety of guarding available to safeguard industrial storage systems. These solutions are critical to ensuring the protection of both the workforce and valuable inventory,” he explained. “For every cause of a debilitating workplace injury — falls to a lower level, falling items, being caught in machinery, and pedestrian/vehicle incidents — there are multiple protective guarding solutions available that can prevent those incidents.”

In addition to safeguarding employees, Niemeyer noted that many companies don’t realize that protective guarding can help optimize operational efficiency. “Not implementing these protective measures can lead to critical system downtime, employee injuries, and damaged products. All of which significantly impact the annual bottom line,” he continued.

For that reason, the presentation will delve into readily available solutions to enhance storage system safety. It will also outline proactive measures and reactive strategies for enhanced productivity. The content primarily targets operations, safety, and maintenance leaders, added Niemeyer.

“This is a great opportunity for those charged with improving employee safety and productivity to gain valuable knowledge about physical, protective, and secure guarding options,” he said. “They’ll learn how to recognize and prioritize the key areas within a storage system that require protection. Some areas are at higher risk than others. This session will help them identify and address those higher potential hazards.”

Active Protective Guarding Technologies Increasingly Available

Presenting “Evolution of Safety” are Mikael Carlsson, Head of Marketing, Business Development, and Mergers and Acquisitions, and Nathan Hulme, Strategic Business Development Manager, both with ProGMA member Troax. The pair will offer a survey of the progressive changes in protective guarding technologies over the past few decades.

“Historically when it came to protective guarding in the industrial workplace, solutions were primarily passive,” Carlsson said. “By that I mean the installation of barriers that physically separate and shield employees from hazards. These include guardrails, bollards, fencing, cages, and other static, fixed barriers.”

Today, as technology has evolved, there are many more active safety solutions, he continued. “Active protective guarding technologies proactively detect and address potential hazards in real-time. They also raise employee awareness of unsafe situations and prevent accidents when a physical barrier isn’t a possibility.”

Examples include visual and audible alert systems that flash or make noise when sensors detect the presence of an employee. They are often installed in and around areas where vehicles (such as forklifts) and workers are both likely to be. These technologies install on forklifts and on barriers to enhance pedestrian safety. They also provide access control, preventing personnel from entering a hazardous area. Other active protective guarding technologies enhance forklift safety and traffic control, triggering collision avoidance systems and reducing travel speeds automatically.

“This session is ideal for anyone interested in learning more about the latest safety and protective guarding technologies available,” added Carlsson. “We’ll be walking through a variety of scenarios and examples to show where both passive and active solutions can reduce an operation’s injury risk.”

ProGMA Members Exhibit Protective Guarding Solutions

Both Niemeyer and Carlsson noted that many of the protective guarding technologies discussed in their education sessions will also be on the MODEX show floor. There, several ProGMA members will exhibit these solutions. They include:

| ProGMA Exhibitor | Booth Number |

| Adrian’s Safety Solutions | B2024 |

| A-SAFE INC | C6277 |

| Boplan USA Inc. | B7215 and B8822 |

| Carron Net Company, Inc. | B4211 |

| Damotech, Inc. | B7236 |

| Dematic | B8019 |

| Folding Guard | B6404 |

| Garlock Safety Systems | B7024 |

| Husky Rack & Wire | B1213 |

| Impact Recovery Systems / SlowStop Guarding Systems | B1219 |

| InCord, Ltd. | B6719 |

| McCue Corporation | B4715 and B4815 |

| Mezzanine Safeti-Gates, Inc. | B7211 |

| Rite-Hite Engineered Solutions Group, Inc | B4007 |

| SpaceGuard Products, Inc. | B7419 |

| Steel King Industries, Inc. | B4824 |

| Troax, Inc. | B6404 |

| WireCrafters, LLC | B5214 |

Although the ProGMA members listed below do not have exhibits at MODEX, attendees can connect with them via mhi.org/progma.

- Bluff Manufacturing

- Heartland Steel Products

- Ideal Warehouse Innovations, Inc.

- Industrial Netting

- Jesco Industries, Inc.

- Wildeck, Inc.

Discover More Protective Guarding Solutions, Resources Online

Can’t wait until MODEX to learn more about how to protect people and assets in your facility? The members of the Protective Guarding Manufacturers Association (ProGMA) offer a variety of resources and educational information about safety solutions. These include a Protective Guarding Search Tool, a list of frequently asked questions (FAQs), case studies, and more.