Wire Mesh Panels Provide Security Across Multiple Warehouse, Manufacturing Applications

Constructed in standard-sized panels for modular installation configurations, wire mesh panels made of steel provide security and protection in a variety of applications throughout warehousing, manufacturing, and distribution operations. The panels can form the basis of a free-standing structure when deployed with posts bolted into flooring, or can be attached to existing structures, such as pallet rack. They feature secured entry gates or doors sized for personnel or forklift access; these entry points can be locked with a variety of methods, from padlock to keypad to electronic passkeys, ensuring that only trained, authorized personnel can access the secured area. Read on for a tour of the most common applications for wire mesh containment panels.

Securing the perimeter of automated equipment and machinery. To keep personnel out of the way of automated systems — such as robotic arms or other powered equipment — steel mesh panels and posts can be used to form a cage around the equipment.

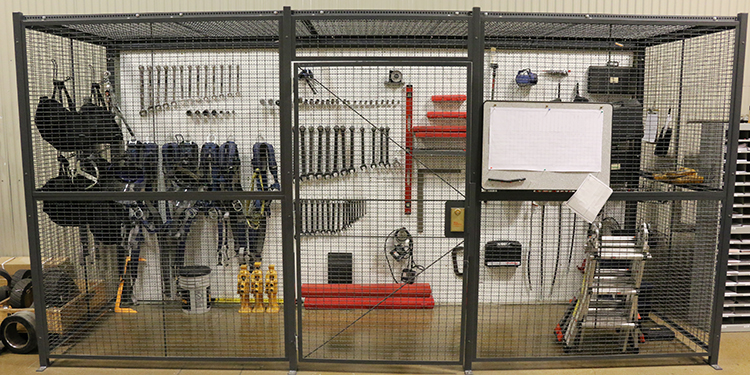

Protecting high value tooling and supplies. Tool cribs storing critical supplies or tooling and dies can be stored in a cage constructed of steel mesh panels and posts. Likewise, caustic chemicals, janitorial supplies, spare parts and other items necessary for facility operation can be secured in these cage structures.

Safeguarding of pharmaceuticals. The U. S. Department of Justice’s Drug Enforcement Administration (DEA) has specific requirements for securing of Schedule III, IV and V drugs as specified in the Title 21 Code of Federal Regulations, Part 1301.72(b). Cages must include 10-gauge (or higher) steel fabric with openings no more than 2.5 inches corner-to-corner; panels mounted securely to 1-inch diameter (or more) steel posts no more than 10 feet apart; and self-closing/self-locking doors. Further, the wall panels must be mounted flush to the floor, and the cage must include a ceiling of identical panels if the sidewalls do not meet the building’s ceiling.

Preventing inventory theft. High-value items can be stored in free-standing cages constructed of steel mesh panels and posts with restricted access via a man-door made of the same materials. Alternately, industrial steel pallet rack bays can be fitted with fixed wire mesh panels bolted to the rack uprights and beams on the back, sides and front; access is typically by a sliding panel (in narrow aisle applications) or one that swings out into the aisle (standard width aisles). Additionally, some facilities install steel mesh panels to prevent stored products from falling off pallets and potentially injuring a person in the aisle below.

Driver cages for delivery personnel. To prevent unauthorized access into a facility via the dock, a cage can be constructed of wire mesh panels that surrounds the egress door. This ensures that a delivery driver must check in at a designated service window integrated with the cage prior to being allowed any further access into the building.

Want more information about using wire mesh panels to enhance security in your operation? The members of the Protective Guarding Manufacturers Association (ProGMA) have produced a series of educational videos showing multiple areas within a facility where these and other guarding systems should be used.