Prioritizing Ergonomics Before Automation: Key Strategies from the EASE Council Tech Talk

As warehouses become more automated, one constant remains: the safety and well-being of the people who keep operations running. That message took center stage during a recent MHI Tech Talk hosted by the Ergonomic Assist Systems & Equipment (EASE) Council. During “Human Advantage—Safety, Ergonomics, and Smart Automation,” industry leaders discussed how companies can design safer, more productive material handling environments.

The Tech Talk featured three EASE Council members:

- Megan Baker, Director of Marketing at UNEX Manufacturing.

- Nate Guralski, Business Director of the Nutting brand at Kito Crosby and Vice Chair of the EASE Council.

- Ron Mack, Sales Manager of Ergonomic Solutions at Blue Giant.

Together, the trio challenged the idea that automation alone solves labor challenges. They also made the case that ergonomics must be part of every strategic decision, long before equipment ever arrives on the warehouse floor.

Why Ergonomics Must Come First

Many organizations think of ergonomics as an add-on. However, Baker argued that it must be embedded into warehouse planning from the beginning.

“Even those that do adopt automation aren’t going to solely do automation,” she said. “There’s always going to be a manual component in daily tasks. That’s why companies should consider ergonomics before, during, and after making any changes in your operation. This is especially important as automation and labor models evolve.”

Instead of reacting to injuries or worker complaints, proactive ergonomics reduces risk and drives efficiency from day one. The goal isn’t just to prevent harm. It’s to design work that supports long-term performance and employee satisfaction.

Although ergonomics is often viewed as a safety cost, its long-term return extends into every part of the business. Reduced injuries lower compensation claims and retraining costs. Well-designed pick and pack zones shorten cycle times. Workers who feel physically supported stay longer, learn faster, and contribute more.

“Ergonomics improves productivity and worker morale,” Mack said. “When you have employees that are comfortable and really enjoying their jobs, you see it in their performance.”

Where Companies Go Wrong

Mack has seen companies invest in expensive ergonomic equipment, only to watch it collect dust. He traces most failures to the same root causes, like ignoring worker feedback and skipping training.

“Workers know all the nuances of their specific processes,” he said. “They’re the best resource for guiding ergonomic improvements.” Without their involvement, even well-intentioned initiatives fall flat.

All three panelists agreed further agreed that if ergonomic initiatives don’t include worker feedback, they won’t stick.

Baker encouraged companies to observe tasks directly and ask about pain points, instead of relying on assumptions. Small insights—how often someone twists to their left versus right, or where they feel strain at the end of a shift—can unlock meaningful design improvements. She described effective ergonomics as an ongoing loop of observation, adjustment, and validation.

Mack also warned against prioritizing functionality over fit. Companies often choose equipment based on specifications rather than how well it integrates into daily tasks.

“Focusing solely on functionality when purchasing ergonomic assist equipment leads to poor adoption,” continued Mack. If workers can’t comfortably use a tool eight hours a day, it doesn’t matter how good it looks on paper.

Misconceptions That Hold Companies Back

Guralski pointed to one of the biggest myths he encounters: that ergonomics is only relevant for office workers. In reality, repetitive lifting, bending, reaching, and pushing put industrial workers at far higher risk of musculoskeletal injury.

He also pushed back against the perception that ergonomic improvements slow down operations.

“Removing physical strains often speeds up work processes,” he said. “Reducing pain points and emphasizing ergonomics with the proper equipment and the solutions can often make employees more productive and an operation more efficient.”

How to Improve Ergonomics Today

Ergonomic improvement doesn’t require a multimillion-dollar automation investment. Many of the highest impact changes begin with simple observation. Guralski advised determining where workers bend too far, reach too high, or push too hard.

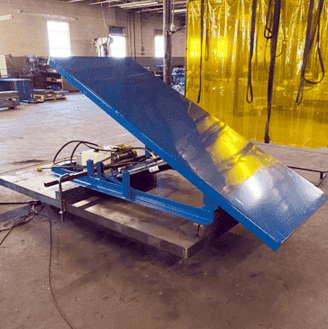

Guralski recommended starting with lift-assist equipment and better cart and caster design. When he helped a heavy-engine manufacturer redesign a pallet cart, every detail centered on how people interact with the load. The scissor-lift platform eliminated deep bending while the casters allowed easy manual movement. Further, because the operation was trying to reduce forklift movement, the design integrated with both tugger and automatic guided vehicle (AGV) systems.

“Because the carts are towable, they could transport up to six pallets at a time and drop them line-side. Now, operators don’t have to use pallet jacks to maneuver the loads,” he recalled. “They have loved these carts. It’s an ergonomic solution that runs safely, smoothly, efficiently, and effectively.”

Mack agreed, noting that simple changes like swapping out static workstations for ones with adjustable height controls can make a significant impact. He advised “an integrated approach that considers physical, cognitive, and organizational support. That includes anti-fatigue floor mats and reach-zone design to better lighting, training, and redesigning the task to match the process.”

Mack further suggested creating focus zones and quiet areas by implementing noise control and adjustable lighting. “When companies consider the whole work experience, they reduce injury risk and maintain throughput.”

Leadership’s Role in Building an Ergonomic Culture

A key success factor in ergonomic equipment adoption, said Baker, is leadership’s commitment.

“You need ergonomics champions within your company,” she said. Those champions need not only authority, but also time and resources to influence process design. She encouraged leaders to spend time on the floor, ask questions, and model participation.

Mack added that leaders must also promote a mindset of continuous improvement.

“You need to do a lot more than just purchase ergonomic equipment. You need to create a shared mindset of safety and ongoing improvement,” he said. When companies reward safe work practices, reinforce proper equipment use, and celebrate ergonomic wins, workers feel ownership over the process. That, in turn, significantly increases the likelihood of usage.

Why Groups Like the EASE Council Matter

When asked why companies should engage with the EASE Council, the panelists pointed to three advantages:

When asked why companies should engage with the EASE Council, the panelists pointed to three advantages:

- Access to other leaders who prioritize safety.

- Education on new ergonomic solutions.

- A forum to ensure human well-being remains part of the automation roadmap.

“When you’re implementing that automation, ensure you’re keeping that primary focus around ergonomics,” Guralski said. “We need to keep employees safe and happy in the future as well.”

Learn More About Industrial Ergonomics

Watch the full recording of the EASE Council’s Tech Talk for more details on integrating ergonomic solutions into an operation. Want to learn more about the benefits of industrial ergonomics? The members of the Ergonomic Assist Systems & Equipment (EASE) Council of MHI are available to consult, answer questions, and make best practice recommendations.