Don’t Make These Three Errors When Specifying And Installing Safety Netting

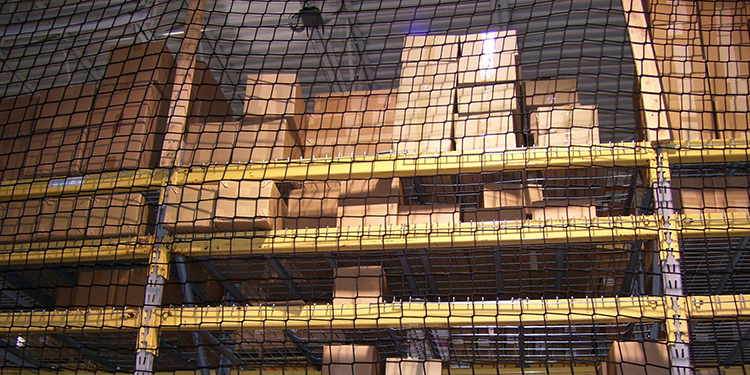

Safety netting provides an essential layer of protection in today’s fast-paced warehousing and distribution environments. These protective guarding solutions—made of woven synthetic fibers—stop falling items from reaching the floor below. However, operations that neglect key application and installation details can experience compromised safety, product loss, and costly downtime.

“Too often, safety netting is an afterthought. Instead, it should be a front-line defense against warehouse injuries and inventory damage,” noted Tammy Raymond, Marketing Director at InCord. The company is a member of the Protective Guarding Manufacturers Association (ProGMA). “It deserves the same degree of consideration as any engineered safety solution.”

Raymond highlighted three common specification-related errors. She also shared how to avoid them when specifying fall-related protection solutions.

Error # 1: Failing to Account for Protection Above the Top Beam

A common oversight in pallet rack safety is assuming protection only needs to reach the height of the top beam. In reality, safety netting must account for the full height of the upright, said Raymond.

“This is especially true for inventory stored at or above that top level. For example, if a beam sits at 20 feet with product stored on it, that becomes the most hazardous point in the rack system due to its height and overhead risk,” she noted.

Ideally, the rack’s design would incorporate taller uprights—such as 25 feet—to accommodate both inventory and safety netting. But in retrofit scenarios, that’s rarely the case.

“The solution is to use an extension system that mounts to the existing uprights,” advised Raymond. “This allows the netting to extend above the top shelf. That provides the necessary containment and prevents product from falling from the highest—and most dangerous—point in the rack.”

Error # 2: Using Inadequate Attachment Methods

You’ve heard the saying—a chain is only as strong as its weakest link. The same holds true for safety netting. Even the most durable net won’t perform as intended if it’s attached with subpar hardware.

“Unfortunately, it’s common to see shortcuts taken here,” Raymond said. “Sometimes operations rely on quick fixes like zip ties or non-rated fasteners when installing nets.”

These attachments don’t just hold the net in place when idle. They’re also responsible for bearing the full load in the event of a fall. If they fail, so does the entire system. That’s why it’s critical to use only the attachment methods and hardware recommended by the manufacturer, she noted.

Error # 3: Improper Installation of Safety Netting

Even the best safety netting won’t perform if it’s installed incorrectly. Unfortunately, it’s just as easy to install a system the wrong way as it is to do it right.

“One of the most common safety netting installation errors is improper use of cable fittings or clamps,” Raymond observed. “Such mistakes that can reduce the system’s holding strength by 40% or more.”

To avoid making this mistake, always follow the net manufacturer’s step-by-step installation instructions carefully. Don’t guess, skip steps, or make assumptions.

“A properly installed system ensures that your netting will perform as designed when it matters most,” she concluded.

Discover Multiple Safety Netting Options

Looking for more details about the different types of safety netting available? Visit Overhead Mesh Guarding, Safety Netting, and Conveyor Guarding in ProGMA’s Protective Guarding Search Tool for examples and suppliers.