Reduce Inefficiencies And Injuries By Combining Ergonomic Solutions With Lean Manufacturing Processes

While they may focus on different areas, there’s a natural synchrony between the principles of Lean manufacturing processes and ergonomic practices: both seek to eliminate waste and downtime while boosting efficiencies. Operations with Lean manufacturing initiatives continuously work toward minimizing unnecessary steps and wasted time that can negatively impact an operation’s productivity, available space, uptime, and throughput rates. Those that employ ergonomics to the design of the tasks workers perform utilize equipment that makes the jobs less strenuous and physically demanding to perform — minimizing the risk of injuries.

The implementation of Lean processes is focused on eliminating what’s often called “The Seven Deadly Wastes.” These are:

- Transportation – Unnecessary movement of inventory, including components, raw materials, and finished products

- Inventory – Excessive amounts of components, raw materials, and finished products held on-site

- Motion – Unnecessary movement of people as they perform work tasks that does not add value

- Waiting – Any dwell time between production processes or movement of work-in-process

- Overproduction – Making more of a finished product before it is actually needed

- Over-processing – Adding unnecessary steps to the production of inventory than is required

- Defects – Finished inventory that are deemed as not meeting quality standards and must be scrapped

Of these, ergonomic solutions can most directly be applied to reducing transportation, motion, and over-processing. As part of a comprehensive Lean analysis of the task or process as its currently performed — typically through a risk assessment — ergonomic factors should be evaluated. These include:

- How much overall space is available in the area where the task is performed?

- What strain-related activities are associated with the task, such as bending, lifting, lowering, carrying, stacking, twisting, stretching, pulling, pushing, squatting, or reaching?

- How much repetition of the same motion occurs during the performance of the task?

- For how long is the operator able to maintain a relaxed, natural posture as the work is performed?

- How much weight is being handled?

- What are the push/pull forces associated with the task?

- What are the physical characteristics of the persons performing the task?

Based on the answers to those questions, a broad variety of ergonomic assist solutions can be applied to eliminate unnecessary movement or to ease the strain on the worker. These systems help to fit the task to the worker — instead of the worker to the task — helping to cut transportation, motion, and over-processing waste. They include:

Work Positioners: These systems come in a variety of styles to support or elevate the load either from underneath or overhead. They include:

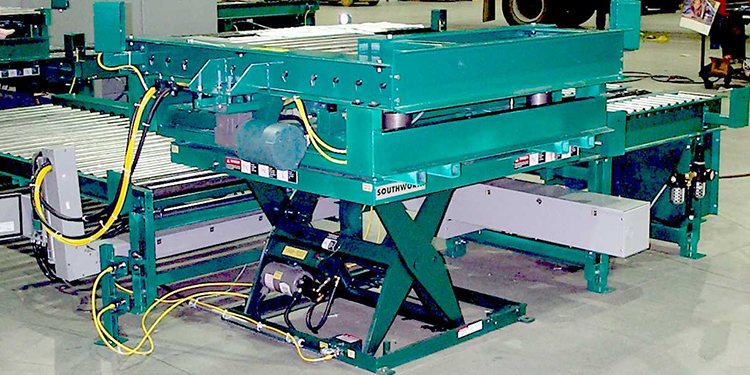

- Lift tables – Devices that support and lift loads to keep them at the optimal working height for an operator. Some include a manual turntable that spins the load to face the operator; others include a tilting function for easier access to the load.

- Pallet positioners – A type of lift table that raises or lowers as the pallet is being stacked or unloaded.

- Tilters – Equipment that mechanically tips a container to give workers easier access to its contents.

- Manipulators – Stationary or portable mechanical arms with attached to a load via tooling, gripper, or forks that counteracts its weight to eliminate worker strain.

- Balancers – Devices support a load from overhead while the operator maneuvers it.

- Vacuum lifters – A device using vacuum technology to attach and lift a load for pick and place tasks.

- Drum turners – Equipment that turns a drum to empty its contents.

- Stackers – Manual or powered lifting devices that move, raise and position loads to comfortable, ergonomic work heights.

Workstations: A workbench or table that adjusts up or down to accommodate workers of various heights. They can also be equipped with a variety of accessories to help better organize the tooling or supplies needed to complete the task in less time and with less movement.

Carts: Manually pushed platforms that ride on wheels or casters with treads optimized for the flooring surface to move items. They can be equipped with drawers, bins, trays, or flat surfaces for material organization.

Pallet rotators: Equipment used to exchange pallets without unstacking the load.

Hand trucks: Similar to a two-wheeled dolly, powered hand trucks can raise and lower the load for easier, more ergonomic handling by the operator.

Roller rack: Inserted into standard pallet rack, these roller devices use gravity to impel a carton to the pick face as the one ahead of it is removed, eliminating reaching and stretching.

Extendible conveyor: Usually located at the dock, these accordion style conveyors can be extended into the back of a trailer to facilitate manual loading and unloading of floor loaded cartons, cutting operator walk time.

In addition to reducing wasted transportation, motion, and over-processing, implementing ergonomic equipment and solutions as part of a Lean manufacturing process will also reduce worker fatigue and the risk of injuries. This, in turn, will further maximize maximizing productivity, accuracy, and quality — and contribute to a reduction in scrap and waste.

Looking for more ways to become more Lean through improved ergonomics? The members of the Ergonomic Assist Systems & Equipment (EASE) Council of MHI are available to help operations implement ergonomic best practices as part of their Lean manufacturing initiatives.