The ROI of Protective Guarding: Why Proactive Safety Pays Off

At ProMat 2025, members of the Protective Guarding Manufacturers Association (ProGMA) delivered a data-driven presentation titled “The ROI of Protective Guarding.” The education session emphasized how proactive safety investments protect people, products, and places while delivering a strong return on investment. The panel made a compelling case for treating protective guarding as an operational necessity, not a discretionary expense.

Speakers included:

- James Augustyniak, Regional Sales Manager at Steel King Industries, Inc.

- Aaron Conway, President of Mezzanine Safeti-Gates

- Dave Dalleske, Senior Vice President of U.S. Sales, A-SAFE Inc.

- Sam Tromblay, Business Development at Rite-Hite

Investing in Protective Guarding Delivers Tangible Returns

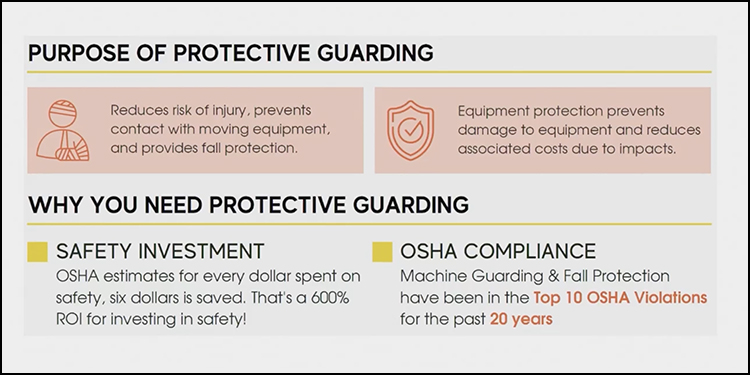

Tromblay opened the session with a statistic from the Occupational Safety and Health Administration (OSHA).

“OSHA estimates that every $1 spent on safety is $6 saved, giving you a 600% return on investment (ROI) when investing in safety,” he said. “When you consider ROI, a single recordable incident requiring medical attention costs an employer $41,000 on average. Guarding installed in those areas can often be less than one single incident with one of those employees.”

![]()

Further, Tromblay explained that workplace injuries have broad ripple effects across operations. These include medical costs, insurance rate hikes, lost productivity, and legal exposure.

“In 2022 alone, U.S. businesses experienced a $167 billion in injury-related costs and lost over 108 million workdays,” he continued, noting that the costs can add up quickly:

- A single recordable injury averages $41,000 in direct employer costs.

- Each fatality costs nearly $1.4 million.

- Total estimated 108 million lost workdays due to injury in 2022.

These figures underscore the key point of the presentation: proactively addressing risks saves significantly more than reacting after the fact. Tromblay encouraged session attendees to evaluate protective guarding as a strategic investment in operational stability.

Guarding People: Compliance, Prevention, and Peace of Mind

Conway focused on perhaps the most critical component of guarding: protecting human lives. As facilities expand vertically to optimize storage and production space, they introduce greater risks for falls. He specifically pointed to mezzanines, pallet drop areas, and pick modules.

Conway stressed that OSHA’s 29 CFR 1910 fall protection regulations require a barrier at all elevated ledges.

“OSHA wants a barrier to be in place at all times, except when you’re actively moving material through the opening. However, OSHA regulations cover a wide range of scenarios. Therefore, follow ANSI standards when there is a question about what type of protective guarding to use. ANSI complements OSHA by addressing specific industrial scenarios more precisely,” Conway said.

For instance, ANSI guidelines recommend dual-gate systems for pallet drop areas. These ensure that at least one gate remains closed, reducing the chance of accidental falls and OSHA violations.

Conway also reminded attendees to “look up” when auditing their facilities. “Assess elevated areas, pallet flow lanes, and rack-supported platforms for fall hazards,” he said. “Guarding isn’t just about avoiding fines. It’s about ensuring your employees go home safely every day.”

Guarding Product: Protecting Inventory from Preventable Damage

Augustyniak emphasized that protecting inventory is about more than minimizing damage; it’s about maintaining a profit center. He cited an annual warehouse inventory damage statistic of 1–2%, with forklifts causing 73% of those incidents. For businesses operating on razor-thin margins, even small losses can have a big impact on the bottom line.

“One facility that budgeted $7,500 monthly for rack repair virtually eliminated that damage after implementing rack-attached barriers and guarding,” Augustyniak recalled. “The operation recouped its investment almost immediately.”

Product protection extends beyond rack guarding, he continued. Examples include:

- Back-of-rack netting to stop goods from falling onto workers or walkways.

- Conveyor guarding to prevent line stoppage due to accidental impacts.

- Assembly area barriers to protect high-value goods during inspection or packaging.

- Impact-rated guardrails to safeguard sensitive systems in automated operations.

In some cases, protective equipment provides triple benefits. It prevents product damage, safeguards workers below, and avoids damage to the facility structure.

“Guarding your product is guarding your revenue,” Augustyniak explained. “And the right solution pays for itself faster than many realize.”

Guarding Place: Infrastructure, Utilities, and Critical Systems

Dalleske expanded the conversation to facility assets. He advised attendees that the costliest damage isn’t always visible on the surface.

“Damaging your concrete, your electrical systems, or your building’s structure doesn’t just require repair. It causes operational downtime, which is often the real cost driver,” he said. In one example, Dalleske described an auto manufacturer with daily production of 350 vehicles valued at $60,000 each. A utility knock-out resulting in just one hour of downtime would cost $1.3 million in lost production.

Dalleske described vulnerable areas like electrical panels, telecommunications closets, data centers, loading dock doors, and door frames. “You can’t just tell forklift drivers to be careful and hope for the best,” he said. “The only effective method is to put physical guarding in place.”

He outlined factors to consider when planning protective guarding within a facility. These included:

- Traffic patterns: Is it a high-traffic or tight-turn area?

- Accessibility: Would repairs shut down key production zones?

- Emergency impact: Could building damage affect evacuation routes?

- Concrete integrity: Will anchoring cause long-term issues?

Dalleske emphasized that installing guarding about more than protecting equipment and structures. It’s about ensuring that operations remain uninterrupted and safe. “Being proactive minimizes risk and maintains your workflow. Safety becomes the byproduct of good planning,” he explained.

Learn More About Proactive Protective Guarding

Throughout the session, all four panelists emphasized one consistent theme: the greatest ROI comes from planning ahead.

“You want to be proactive, not reactive,” Dalleske concluded. “That’s the time to install the right solution. Waiting until after an incident means scrambling for a quick fix that may not actually address the root issue.”

ProGMA members offer free facility assessments and consultation. Comprised of 23 member companies, the organization offers both tools and expertise to help companies select the optimal guarding for their operations. Visit the website at mhi.org/progma.