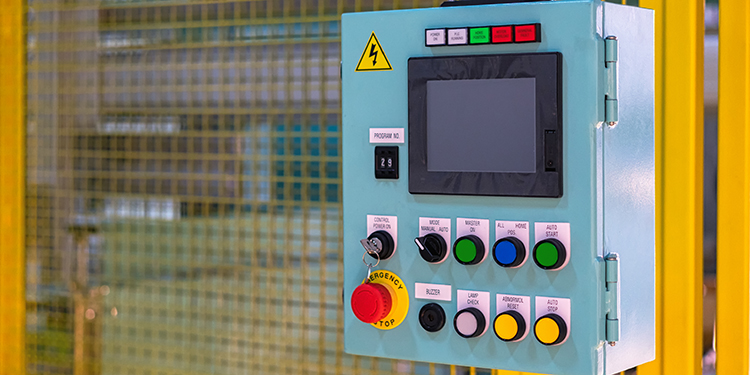

Virtually every piece of equipment or machinery installed in warehouse, distribution center, or manufacturing facility requires an electrical panel or cabinet located in close proximity to provide power to the system. Yet leaving these sensitive housings exposed to potential damage from traffic within the operation — such as forklifts, automatic guided vehicles (AGVs), autonomous mobile robots (AMRs), tuggers, or other motorized vehicles — increases the risk of damage due to a collision, impact, or other accidental contact. Such an incident can cause a fire or expose personnel to electrical shock — not to mention expensive damage to complex equipment and unscheduled downtime.

To reduce these risks there are a variety of protective industrial guarding solutions available, including wire mesh partitions, machine guarding, bollards, guardrails, and other physical barriers that can be installed around electrical panels and cabinets. The choice of which solution (or combination of solutions) will provide the optimal degree of protection is influenced by a variety of factors. However, regardless of the industrial guarding chosen, there are four applicable safety standards that must be observed regarding its use and placement around the electrical panel or cabinet to be protected. They include:

The National Fire Protection Association’s NFPA 70: National Electrical Code (NEC). Adopted by all 50 states, this standard establishes the benchmark for safe electrical design, installation, and inspection to protect people and property from electrical hazards.

NFPA 70E: Standard for Electrical Safety in the Workplace. This standard lists the requirements for safe work practices to protect personnel by reducing exposure to major electrical hazards. It helps companies and employees avoid workplace injuries and fatalities due to shock, electrocution, arc flash, and arc blast.

NFPA 79: Electrical Standard for Industrial Machinery. This document provides safeguards for industrial machinery to protect operators, equipment, facilities, and work-in-progress from fire and electrical hazards. It also required that open space left around the panel or cabinet for the purposes of access not be used for storage of other materials.

Occupational Safety and Health Administration’s OSHA 1910 Subpart S, specifically section 1910.303(g)(1) – Space about electric equipment. It requires that “Sufficient access and working space shall be provided and maintained about all electric equipment to permit ready and safe operation and maintenance of such equipment.” Sub-sections offer additional details about the minimum amount of open space that must be maintained around the electrical panel or cabinet. This includes guarding placement in terms of the specific minimum depth and width dimensions required for working space needed for opening any access doors in order to inspect, service, or maintain the electrical equipment. The sub-section also includes details about the size and location of access entrances within the guarding.

Looking for more details about using guarding to protect sensitive equipment within your operation? The members of the Protective Guarding Manufacturers Association (ProGMA) have produced a series of educational videos showing multiple areas within a facility where these and other guarding systems should be used.