Alternative Solution For Fall Prevention In Empty Pick Module Pallet Bays

Associates working within pick modules or on shelving within rack-supported platforms typically pick product from pallets delivered to them via forklifts on the aisle side ledge. For the purposes of forklift access, removable guarding (also called handrails) or chains should be used to protect these openings at a minimum. But, should a worker forget to replace the safety device and someone approaches the unprotected ledge, the risk of a fall increases significantly.

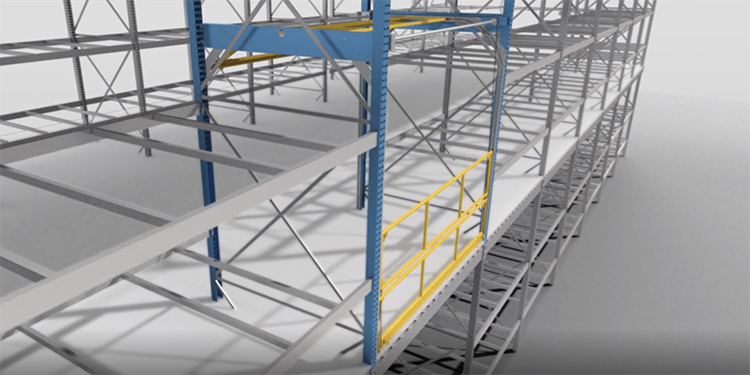

In addition to removable guarding and chains, another option for securing empty pick module pallet loading positions is a dual gate system. Offered by many of the members of the Protective Guarding Manufacturers Association (ProGMA), these systems incorporate two interconnected protective barriers—one at the ledge opening where pallets are placed, the other at the associate side of the pick module.

When one side of the gate is down to prevent access to the pallet opening, the other side is up to allow access. This prevents a worker from entering an open bay when pallets are being loaded; conversely, it prevents pallet loading when workers are picking within the area.

Dual gate systems can be designed as a single-piece, welded unit, or as two separate gates that slide up and down on a rail; both styles create a visual and physical barrier that protects associates working within pick modules. They can be installed in both pallet bays and empty pallet return areas in a pick module. Installation options include manual (push/pull), semi-automatic (push button) or fully automated (triggered by sensors) operation. For additional product fall protection, the gates can be further enhanced with devices such as netting or wire mesh.

Although they are available as a retrofit for an existing pick module, the optimal and most cost-effective time to add a dual gate system to every pallet opening is during the initial design phase. This ensures that the system will account for obstacles such as conduit or sprinkler heads, or obstructions such as building columns.

Want more information about the different types of rack safety equipment? Visit ProGMA’s section of Frequently Asked Questions (FAQs), here.