ProGMA’s ProMat Educational Session Shares How To Apply Protective Guarding To Reduce Risk

Keeping workers safe is a top priority across manufacturing, warehousing, and distribution operations. One of the best ways to safeguard against injuries is to apply protective guarding to reduce risk throughout a facility. That’s why operations, maintenance, and safety managers won’t want to miss the free education session, “5 Common Hazards To People, Products & Facilities: How Proper Protective Guarding Can Help Mitigate Risk.” The members of the Protective Guarding Manufacturers Association (ProGMA) will present this session at ProMat 2023 on Tuesday, March 21, from 2:15 – 3:00 p.m. Central time in Theater H on the show floor in the South Exhibit Hall.

Session Speakers’ Focus on Protective Guarding to Reduce Risk

Session speakers are ProGMA members Paul Barlow, CEO of A-SAFE; Marc Rousseau, Vice President of National Accounts at Damotech; and Kyle Nobile, Senior Engineer at Bluff Manufacturing. The trio noted the importance of applying innovation to safeguard people, equipment, and building structures. Their presentation will therefore showcase some of the latest improvements to existing solutions.

“Anyone who cares about keeping their employees safe should attend this session,” noted Nobile. “It’s a great opportunity to learn how to better protect workers from common safety risks in industrial facilities. We’ll be discussing both solutions and specific approaches to improve the safety of people, products, and facilities.”

“We will specifically share information about the five most hazardous areas that should utilize protective guarding in a facility,” said Rousseau. He pointed to National Safety Council statistics estimating the total cost of workplace injuries in industrial and supply chain facilities in 2020 was $163.9 billion. “When compared to the cost of an accident, the cost of the guarding is exponentially less.”

Additionally, for the past 19 years, improper machine guarding ranked in the Top 10 Occupational Safety and Health Administration (OSHA) violations. For that reason, added Barlow, the session will explore “how to select the correct, fit-for-purpose protective guarding to reduce risk throughout an operation. There are a variety of solutions that are readily available to address safety concerns.”

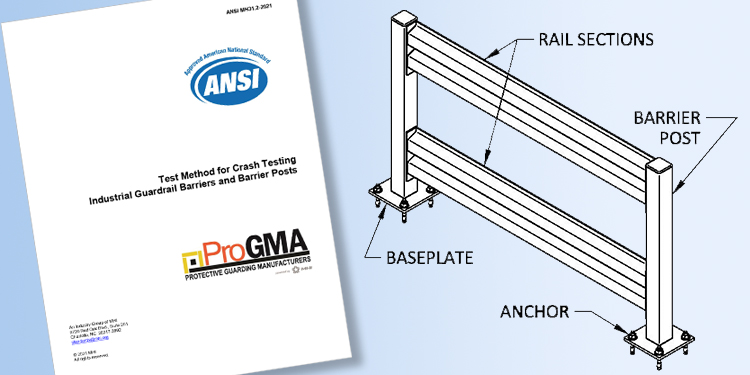

Discussion on New Guardrail Standard

The presentation will also share details about ProGMA’s new safety standard. ANSI MH31.2 – Test Method for Crash Testing Industrial Guardrail Barriers and Barrier Posts established a standardized performance testing method. These tests assess the performance of these protective guardrails against motorized vehicle and forklift impacts in industrial and warehouse environments. Previously, no such standard existed, noted Barlow.

“Nearly every manufacturer of steel and/or polymer bollards, industrial facility protection guardrail, and industrial pedestrian guardrail tests their products’ performance in an impact,” he explained. “However, the testing process may be different for each manufacturer.”

That lack of testing consistency makes it difficult for those seeking to compare products based on performance. ANSI MHI31.2 allows a facility operator to evaluate different options when seeking protective guarding to reduce risk. The standard covers products used for safeguarding pedestrian walkways, critical equipment, rack structures, automated machinery, facility columns, corners, walls, electrical, and ventilation equipment.

Key Takeaways

“Session attendees will come away with a concise understanding of a facility’s most common safety and security challenges,” continued Rousseau. “We will discuss both process improvements and the application of protective guarding to reduce risk. Participants will learn multiple ways to identify and mitigate the potential safety hazards that could harm their people and assets.”

Those attending the presentation will also see specific examples of safety-related problem areas in facilities, added Nobile. “Participants will come away with a better understanding of how to prevent injuries, and damage to products, equipment, and facility structures.”

The presentation will also highlight several resources available from ProGMA to further help manufacturing, warehousing, and distribution operations enhance safety. These include the Protective Guarding Checklist and the Protective Guarding Search Tool.

Unable to make it to the ProGMA education session in person? The presentation and its audio recordings will be available online after the conclusion of ProMat. Registration for the entire event — including all education seminars — is free.

ProGMA Members Exhibit Protective Guarding To Reduce Risk

Additionally, several ProGMA members will be exhibiting protective guarding products at ProMat 2023. They include:

| ProGMA Member | Booth Number |

| A-SAFE | S1041 |

| Adrian’s Safety Solutions | S3338 |

| Bluff Manufacturing | N6719b |

| BoPlan USA Inc | N241 |

| Carron Net Company, Inc. | S1814 |

| Damotech, Inc. | S1755 |

| Folding Guard® | S231 |

| Garclock Safety Systems | S4223 |

| Husky Rack & Wire | S1763 |

| Ideal Warehouse Innovations, Inc. | S3350 |

| InCord | S1172 |

| McCue Corporation | S1063 |

| Mezzanine Safeti-Gates Inc. | S1749 |

| Rite-Hite | S1536 |

| SlowStop Guarding Systems, LLC | S668 |

| SpaceGuard Products, Inc. | S1268 |

| Steel King Industries, Inc. | S1941 |

| Troax, Inc. | S412 |

| WireCrafters, LLC | N7534 |

Although ProGMA members listed below do not have exhibits at ProMat, their representatives will be at the show. Connect with them through MHI’s exhibit in Booth N6500 or by visiting mhi.org/progma.

- Heartland Steel Products

- Industrial Netting

- Jesco Industries, Inc.

- Wildeck, Inc.

Looking for more types of protective guarding to reduce risk and safeguard facility personnel and structures? The members of the Protective Guarding Manufacturers Association (ProGMA) curate a Protective Guarding Search Tool, a comprehensive listing of nearly 40 different solutions to make an operation safer.