How To Identify Areas Where Rack Guarding Is Needed

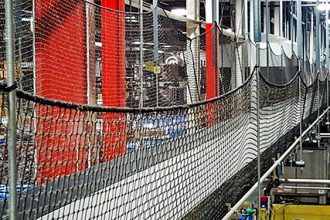

Protective steel mesh containment panels — also called rack back, rack safety panels, or rack guarding — are attached to the uprights (columns) on the sides, back or face of industrial steel storage rack. These panels prevent pallets or products from falling off the sides or back of a pallet rack by “catching” them if they are dislodged, or if the load is not placed precisely on the beams by a forklift operator.

But not every rack in every facility will necessarily need rack guarding; in fact, many operations don’t even consider installing it until they experience a “near miss” or an accident that results in injured personnel, or damage to equipment, vehicles or the facility. Therefore, to determine where these protective panels should be installed, it’s important to regularly observe each rack structure’s surroundings. Here are a few key attributes to look for when assessing areas in greatest need of rack guards for personnel and product safety:

- High volume pedestrian and vehicle traffic. Main aisles or walkways adjacent to racking that are regularly traversed by personnel on foot or on vehicles, such as forklifts or tuggers, have an increased risk of exposure to an injury caused by a pallet, product or carton falling from overhead. Adding rack guarding prevents items from dropping into these high traffic areas.

- Work cells or equipment in close proximity to racking. Employees assigned to perform specific tasks in designated locations are at high risk of being struck by an object falling from a rack in close proximity to their workstation. Installing containment panels to the racking keeps their area safe from falling item hazards. Further, if racking is located near machinery, equipment, or a loading dock (either indoors or outside), adding rack guarding prevents stored pallets and cartons from tumbling into these areas. In dock areas, it also offers an additional measure of protection against pilferage from visitors, such as truck drivers.

- Non-unitized, loose loads. Pallets of loose products that are not unitized with stretch wrap pose a high risk of falling objects, particularly from upper rack bays, as they are placed or removed by forklift. To prevent that situation, rack guarding can be installed from the floor to the ceiling, including extending above the top of the rack columns in applications where the height of the upper-most stored pallet load is taller than that of the rack structure.

- Pallet loads that overhang the rack beams. Some racking is designed to be narrower in depth than that of the pallets that rest upon its beams. However, if a forklift driver does not place the load precisely, it could topple off the back of the rack. Installing rack guarding to the back of the storage structure will prevent the load from tipping off the beam and falling to the floor below.

- Facility structures vulnerable to an impact. To maximize floorspace, some rack installations are positioned against a wall or a structural column in the building. Further, plumbing, sprinkler pipes and electrical conduit running along walls or columns can also be located behind racking. Utilizing steel mesh containment panels on the back of the rack protects these structural features and utility lines from an impact by a load or pallet placed too far back in the rack by a forklift driver. It also saves money by preventing damage to critical utilities and building structures.

- Areas where flue spaces are required for fire suppression. Back-to-back racks are required by the National Fire Protection Association’s NFPA 13 design standard to have a minimum 6-inch flue space clear of obstructions. If a product encroaches too far (or tumbles) into this space, the fire might vent out instead of up and the sprinklers may not be activated quickly enough, nor be able to provide adequate coverage. With the addition of wire mesh rack guarding, an operation can be assured that the flue space will remain clear and in compliance with the requirement.

Although steel mesh containment panels can be easily retrofitted to an existing, reconfigured, or relocated rack system, the optimal and most cost-effective time to specify rack guarding is during the initial design phase. This ensures that the system will account for obstacles such as conduit, sprinkler heads, electrical outlets, building columns or any other obstruction. Should racking be relocated or new rack added to an operation, repeat the assessment process to determine the degree of risk falling items may pose to personnel, equipment, or building features in this new location.

Want more information about rack guarding? The members of the Protective Guarding Manufacturers Association (ProGMA), offer the standard, “ANSI MH31.1-2019 – Steel Mesh Containment Panels Used In Vertical Storage System Applications: Performance and Testing Requirements,” available for purchase.